ERNESTO® Rotwein-/Weißw.-/Sekt-/Wassergläser

14,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

Ewers Strickstrumpfhose Ewers Mädchen 2er Pack Str...

14,75 €

OTTO

ab 4,20 Versandkosten

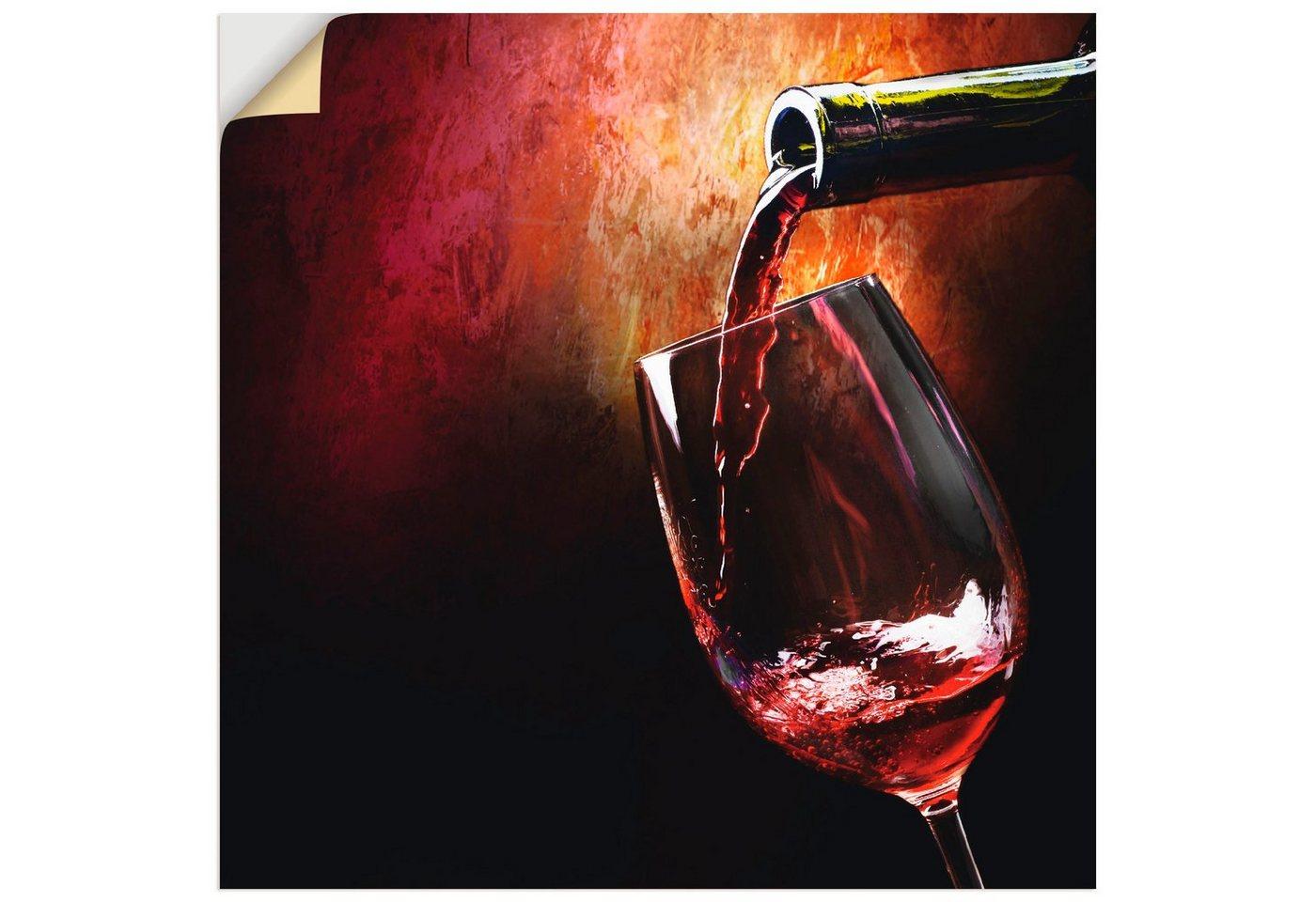

Artland Glasbild Wein - Rotwein, Getränke (1 St),...

27,99 €

OTTO

ab 2,95 Versandkosten

Artland Glasbild Wein - Rotwein, Getränke (1 St),...

65,99 €

OTTO

ab 2,95 Versandkosten

Artland Glasbild Wein - Rotwein, Getränke (1 St),...

130,99 €

OTTO

ab 2,95 Versandkosten

Artland Glasbild Wein - Rotwein, Getränke (1 St),...

120,99 €

OTTO

ab 2,95 Versandkosten

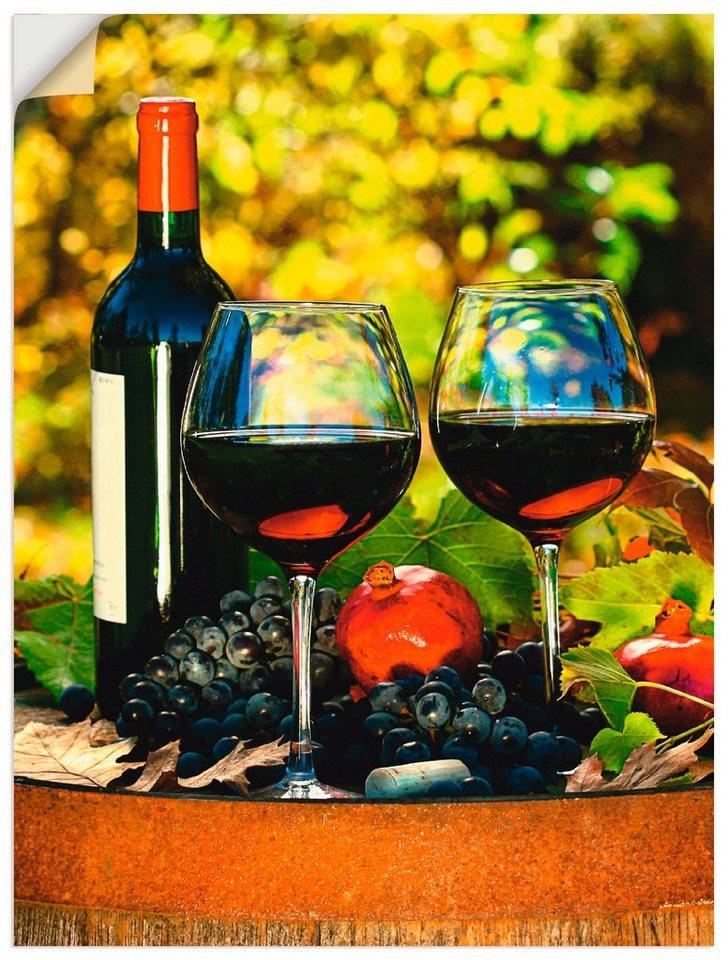

Artland Glasbild Gläser Rotwein auf altem Fass, Ge...

37,99 €

OTTO

ab 2,95 Versandkosten

Artland Glasbild Gläser Rotwein auf altem Fass, Ge...

27,99 €

OTTO

ab 2,95 Versandkosten

Artland Glasbild Gläser Rotwein auf altem Fass, Ge...

120,99 €

OTTO

ab 2,95 Versandkosten

Artland Wandbild Gläser Rotwein auf altem Fass, Ge...

19,99 €

OTTO

ab 2,95 Versandkosten

Artland Wandbild Gläser Rotwein auf altem Fass, Ge...

37,99 €

OTTO

ab 2,95 Versandkosten

ERNESTO® Rotwein- / Wassergläser, Kristallglas

11,99 €

Lidl Online-Shop

ab 5,95 Versandkosten

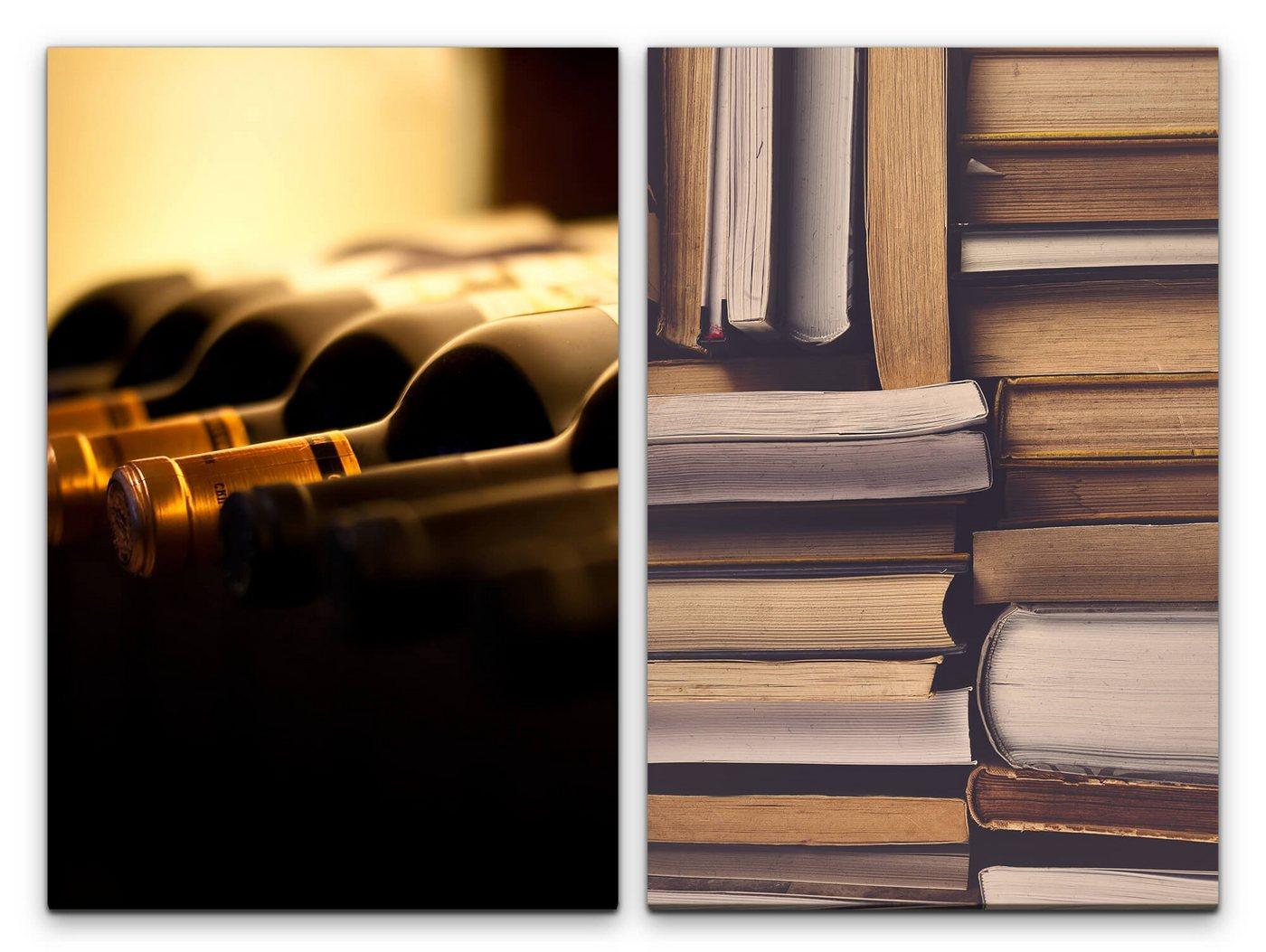

Sinus Art Leinwandbild 2 Bilder je 60x90cm Bibliot...

37,00 €

OTTO

ab 7,00 Versandkosten

Sinus Art Leinwandbild 2 Bilder je 60x90cm Klavier...

37,00 €

OTTO

ab 7,00 Versandkosten

Sinus Art Poster Künstlerische Fotografie Rotwein...

12,00 €

OTTO

ab 7,00 Versandkosten

Artland Holzbild Wein - Rotwein, Getränke (1 St),...

43,99 €

OTTO

ab 2,95 Versandkosten

Artland Wandbild Wein - Rotwein, Getränke (1 St),...

25,99 €

OTTO

ab 2,95 Versandkosten

Artland Wandbild Wein - Rotwein, Getränke (1 St),...

24,99 €

OTTO

ab 2,95 Versandkosten

Artland Wandbild Wein - Rotwein, Getränke (1 St),...

32,99 €

OTTO

ab 2,95 Versandkosten

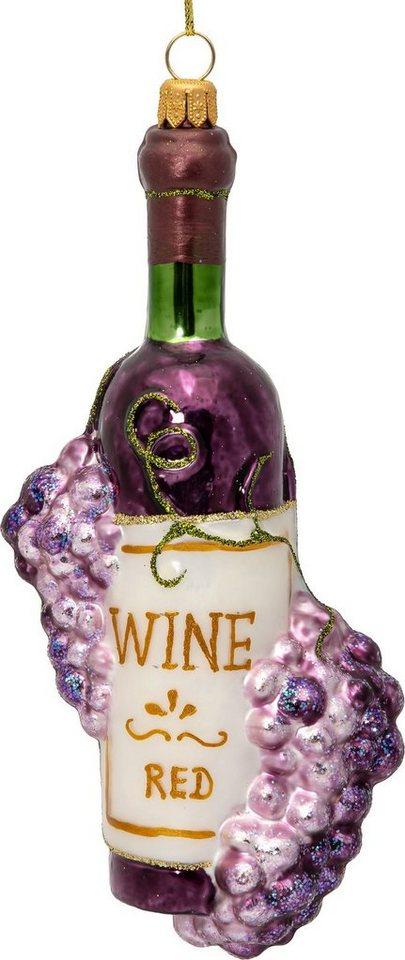

SIKORA Christbaumschmuck BS745 Rotwein Weinflasche...

36,95 €

OTTO

ab 4,95 Versandkosten